ABOUT YOUR EQUIPMENT

In this lesson you will be learning about the different types of vehicles, towing equipment and rigging that a light-duty operator will use on a day-to-day basis. It is vital that an operator understands what everything on their vehicle is used for before they begin their towing operations.

PARTS OF A CARRIER

The car carrier, commonly referred to as a flatbed or a rollback, is one of the most commonly used towing vehicles. The truck is fitted with a large moveable bed that can be lowered and angled so a vehicle can be winched onto it.

Review the images below and descriptions below to understand the appearance and purpose for the parts of a car carrier.

- Winch – The winch is the mechanical device that extends and retracts the wire rope or synthetic cable. It can pull objects with thousands of pounds of force.

- Controls/Levels – The controls or levers are used to operate the winch and extendable boom.

- Winch line / Wire Rope – The winch line is a wire or synthetic rope used to winch vehicles or other objects towards the wrecker.

- Freespool – A device that allows that winch line to extract without any tension.

- Wheel lift / Underreach – A mechanical device used for raising and lowering vehicles. Casualties can be secured to the wheel lift or underreach via locking mechanisms.

- L Arms – Adjustable arms that connect to the wheel grid on either side of the casualty’s wheels.

- Crossbar for wheel lift – The crossbar attaches the wheel grid to the wheel lift. It can be adjusted for the width of a casualty.

- Key-hole slots – Slots that can be fitted with hooks for towing purposes.

CARRIER REAR VIEW – LIGHTS & BEACONS

- Emergency Warning lights/Beacon – The rotating lights typically on the roof of carrier’s cab. Their primary function is to alert the motoring public of roadside work.

- Marker lights – Lights along the side of the carrier deck.

- Work lights – Lights used to illuminate the area behind the carrier for working at night.

CARRIER SIDE VIEW – TRUCK & RIGGING

- Hydraulic Cylinder – A device that extends and retracts the wheel lift.

- Cab – The driver compartment of a carrier. It can only carry as many operators or customers as it has seatbelts.

- Tail board – The end lip of the carrier deck.

- Cargo containers / Storage Compartments – Containers for storing items towing equipment and materials.

- Cones – Cones or pylons used for traffic control.

- Garbage container – A receptacle for garbage, debris or anything else cleaned up from a scene.

CARRIER REAR VIEW – TRUCK & RIGGING

- Spot / Convex Mirrors – Mirrors used when driving and backing up the carrier.

- Tail Board – the back end of the wrecker that houses the tail lights and will have D-rings and attachment points. If the wrecker is fitted with a sling, it will be attached to the Tailboard.

- Mud Flaps – A set of rubber screens behind tires that prevent mud or other debris from behind flung backwards from the tires of a vehicle.

- Secondary Attachment Chains – chains used as a failsafe in the event the main point of securement fails.

- Body – The driver compartment of a carrier. It can only carry as many operators or customers as it has seatbelts.

PARTS OF A WRECKER

-

A Wrecker, also commonly referred to as a boom truck, is a truck that is designed to lift and tow a vehicle with a device called an wheel lift or a under reach.

Review the images below and descriptions below to understand the appearance and purpose for the parts of a wrecker.

WRECKER SIDE VIEW – TOWING EQUIPMENT

- Extendable boom / Raiseable boom – An extending lifting device. The winch line runs through to lift the vehicle.

- Hydraulic Cylinder – The hydraulic cylinder(s) lifts, extends and retracts the boom.

- Winches – The winch is the mechanical device that extends and retracts the wire rope or synthetic cable. It is capable of pulling objects with thousands of pounds of force.

- Controls / Levels – The controls or levers are used to operate the winch and extendable boom.

- Winch line – The winch line is a wire or synthetic rope used to winch vehicles or other objects towards the wrecker.

- Boom Head – The boom head is located at the end of the extendable boom and can be fitted with sheaves or pulleys.

- Sheave head – The sheave head controls the wire or synthetic rope as it comes off of the extendable boom.

- Wheel lift / Underreach – A mechanical device used for raising and lowering vehicles. Casualties can be secured to the wheel lift or underreach via locking mechanisms.

- Tow sling – A device used to lift and transport a vehicle using chains off its bumper. Though they are less commonly used today, slings were at one time the standard equipment for towing vehicles.

- Wheel Freespool – A device that allows that winch line to extract without any tension.

WRECKER REAR VIEW – TOWING EQUIPMENT

- Spot / Convex Mirror – Mirrors used when driving and backing up the carrier.

- Cab – The driver compartment of a carrier. It can only carry as many operators or customers as it has seatbelts.

- Tail Board – The back end of the wrecker that houses the tail lights and will have D-rings and attachment points. If the wrecker is fitted with a sling, it will be attached to the Tailboard.

- Mud Flaps – A set of rubber screens behind tires that prevent mud or other debris from behind flung backwards from the tires of a vehicle.

- Secondary Attachment Chains – chains used as a failsafe in the event the main point of securement fails.

- Manufacturer Tag – A sticker or tag containing information about the boom’s specs.

WRECKER SIDE VIEW – LIGHTS & BEACONS

- Beacon / Emergency Warning lights – The rotating lights typically on the roof of carrier’s cab. Their primary function is to alert the motoring public of roadside work.

- Work Lights – Lights used to illuminate the area behind the carrier for working at night.

- Marker Lights – Lights along the side of the carrier deck.

WRECKER REAR VIEW – LIGHTS & BEACONS

- Beacon / Emergency Warning lights – The rotating lights typically on the roof of carrier’s cab. Their primary function is to alert the motoring public of roadside work.

- Work Lights – Lights used to illuminate the area behind the carrier for working at night.

- Marker Lights – Lights along the side of the carrier deck.

WRECKER REAR VIEW – TRUCK & RIGGING

- Spot / Convex Mirror – Mirrors used when driving and backing up the carrier.

- Cab – The driver compartment of a carrier. It can only carry as many operators or customers as it has seatbelts.

- Tail Board – The back end of the wrecker that houses the tail lights and will have D-rings and attachment points. If the wrecker is fitted with a sling, it will be attached to the Tailboard.

- Mud Flaps – A set of rubber screens behind tires that prevent mud or other debris from behind flung backwards from the tires of a vehicle.

- Secondary Attachment Chains – chains used as a failsafe in the event the main point of securement fails.

- Manufacturer Tag – A sticker or tag containing information about the boom’s specs.

WIRE ROPE

The wire rope is one of the two commonly used winch lines. In the towing industry, we do not refer to this piece of equipment as a cable. The line itself is capable of withstanding thousands of pounds of force and when it is connected to the power source of the winch, it can be used to pull objects towards the wrecker or car carrier.

Important information about the wire rope:

- The wire rope is a live machine. This means that it must be treated as carefully as any other piece of mechanical equipment on your truck.

- The wire rope is wound around the winch drum and must be wrapped a minimum of five wraps before the winch can be engaged.

- The rope should be routinely inspected for burrs, kinks, flat spots, broken wires, elongation, rust, dry spots and other types of damage.

- A visual inspection of the wire rope is required every day that it is in use.

- The two common types of wire rope are steel core and fiber core:

- Steel core is used for larger wreckers as it is stronger and more resistant to crushing.

- Fiber core is mostly used on smaller trucks as it requires less maintenance and holds lubricant longer.

- Every wire rope will come a working load limit (WLL). If you are unsure of the WLL of your trucks wire rope, ask a supervisor in your company or take the steps to learn the information yourself.

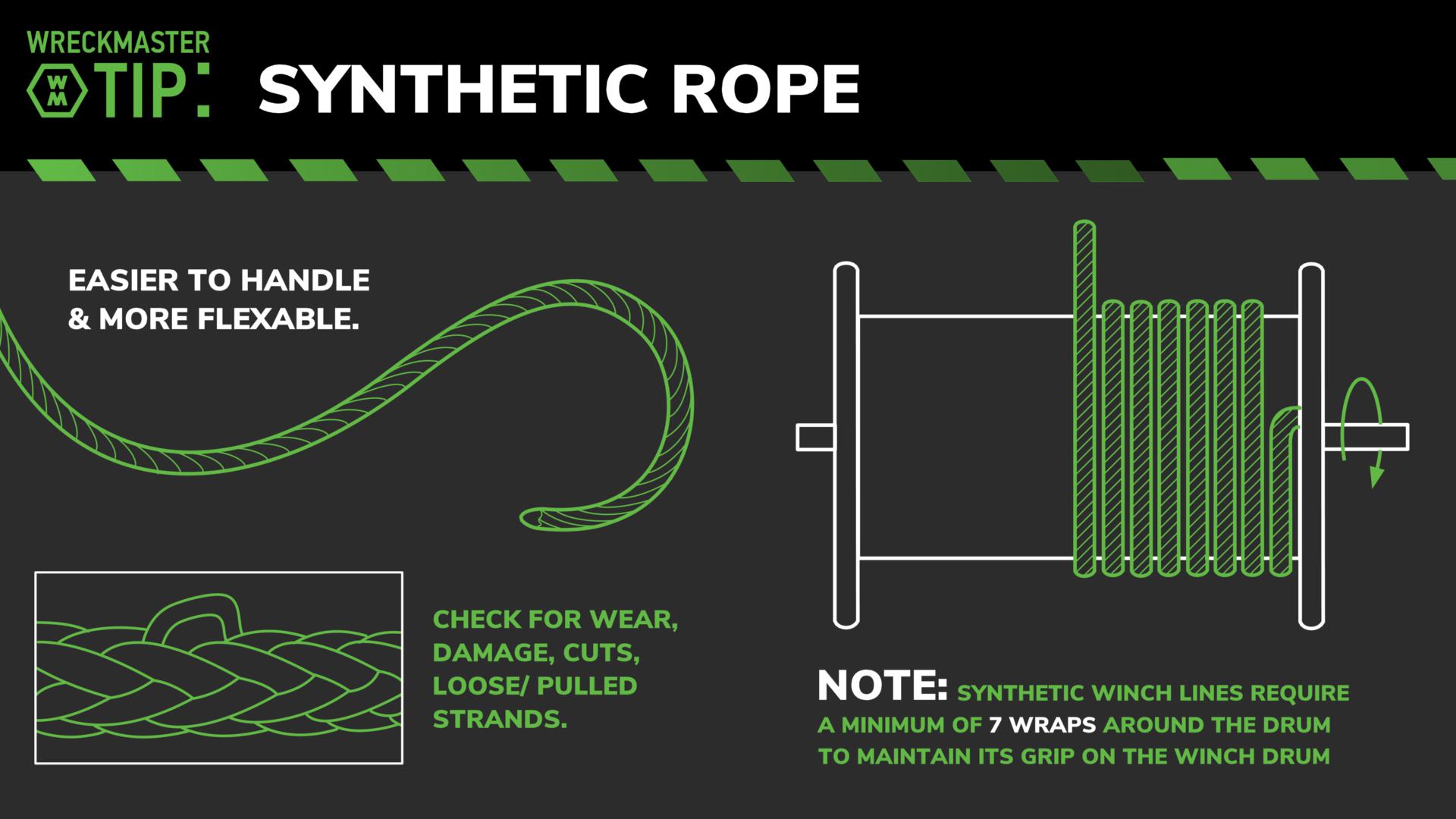

SYNTHETIC ROPE

The synthetic rope is the second most commonly used type of line used in towing. Like the wire rope, it is connected to the winch for a power source and can be used to pull thousands of pounds towards the carrier or wrecker.

Important information about synthetic rope:

- The synthetic rope is a live machine. This means that it must be treated as carefully as any other piece of mechanical equipment on your truck.

- The synthetic rope is wound around the winch drum and must be wrapped a minimum of seven wraps before the winch can be engaged.

- The rope should always be used with a clean or new winch drum that is thoroughly inspected for burrs, catch points or anything else that could damage the rope.

- The rope should be inspected every day that it is in use for wear, damage, cuts and loose or pulled strands.

- Every wire rope will come a working load limit (WLL). If you are unsure of the WLL of your trucks synthetic rope, ask a supervisor in your company or take the steps to learn the information yourself.

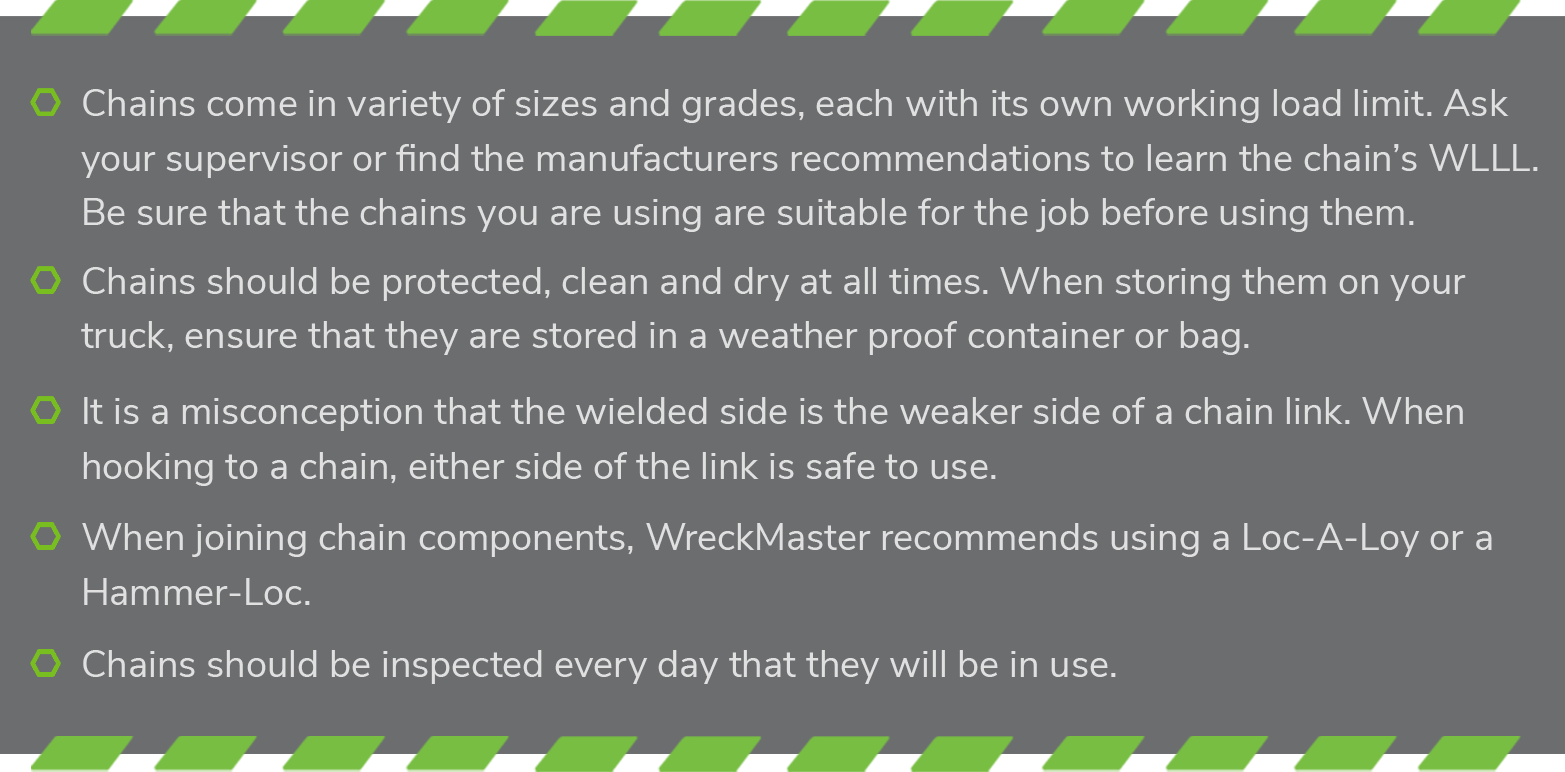

CHAINS

Chains are important pieces of equipment for any operator. While they have many different uses in the towing world, as a light-duty operator you will typically be using them for secondary securement purposes.

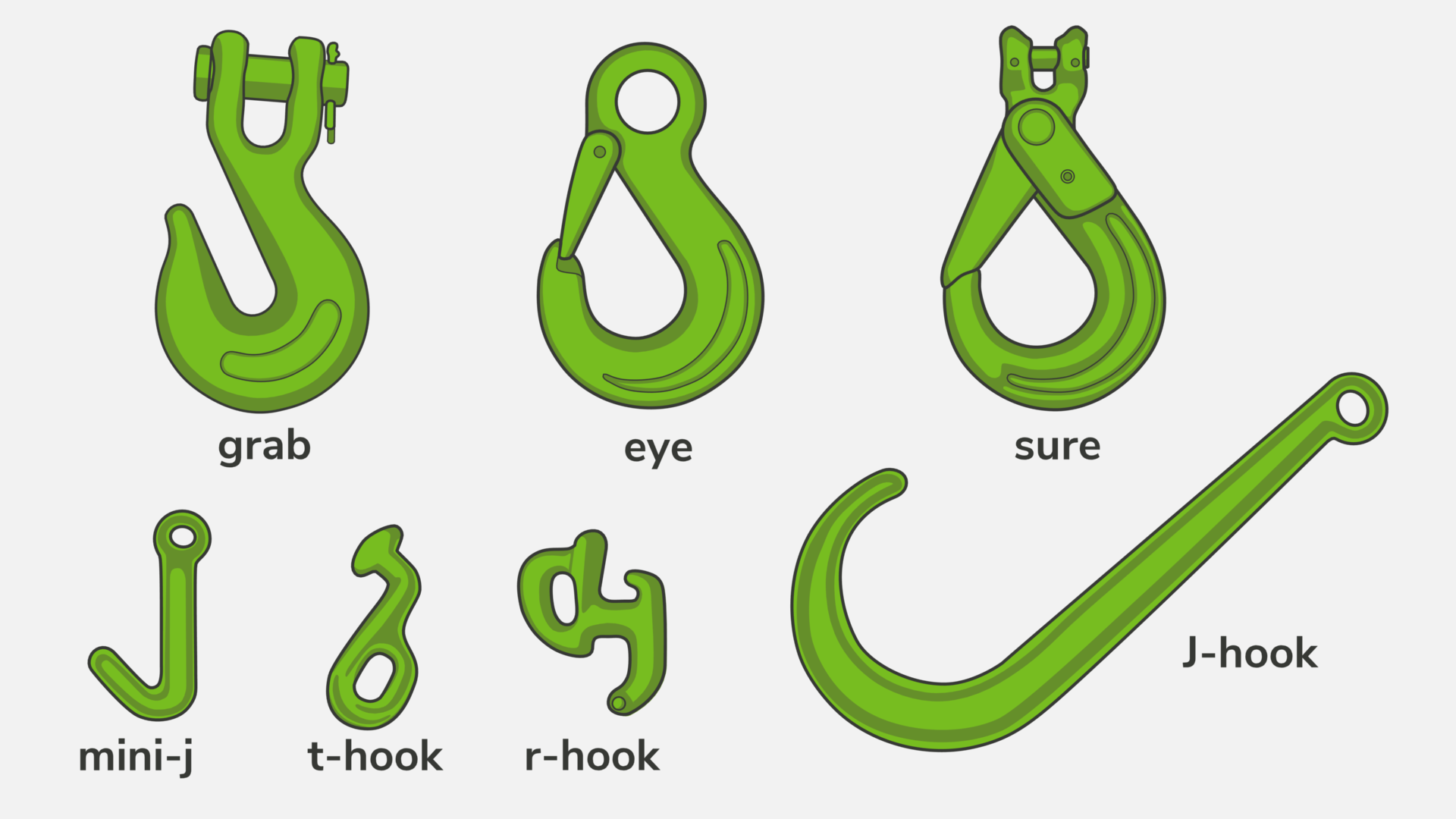

HOOKS

Hooks are essential tools for loading casualties and come in many different shapes and sizes. They are often found in a cluster at the end of a strap or chain.

When using a hook in a cluster, WreckMaster recommends securing the loose hooks together to avoid them catching onto items such as the roadway or securement slots on the carrier bed.

REMEMBER

A hook should always face up unless it will damage the casualty.

STRAPS

Straps come in a variety of lengths, grades and sizes. They should be regularly inspected for damage such as fraying and cuts.

Important information about straps:

- Straps are typically made of nylon fabric and are far more susceptible to cutting and damage. To avoid damage:

- Use wear pads on sharp edges.

- Crib sharp objects with rubber or wood.

- Straps are lighter than chains and are generally easier to work with.

- Straps capture more of the load and are more forgiving on the load, making them less likely to cause damage.

- Straps come with a working load limit. This information can be found on the straps tags or from the manufacturer.

OTHER EQUIPMENT

Here are some other types of equipment a light-duty operator will use:

SNATCHBLOCK

A snatch block is a pulley system commonly used in the towing industry. It can be employed to gain a mechanical advantage or redirect a line. It should be inspected any day that it will be in use.

BUCKLES

ckles are a device that is used to shorten or organize straps. The can also be used to turn a strap into a bridle for towing purposes.